Maintenance, Repair and Overhaul (MRO) is the operational heart of aviation safety. Today, operators are under pressure from rising fleet sizes, ageing airframes, and a hard-to-fill pipeline of skilled technicians. AI, machine learning and robotics are quickly becoming the practical tools needed to reduce unplanned downtime, improve inspection accuracy and make scarce technicians far more productive. Below we explain how these technologies work in practice, why the economics make sense, and how MRO managers and technicians can prepare.

Why change is urgent: market size and the technician gap

The scale of the MRO opportunity and the depth of the labor challenge pushes the industry toward automation. The global aircraft MRO market was estimated to be USD$90.9 billion in 2024 and is projected to grow to USD$120.96 billion by 2030, as fleets expand and ageing aircraft require more service.

Meanwhile, a long-term personnel forecast from Boeing expects demand for roughly 710,000 new maintenance technicians worldwide over the next 20 years to support commercial growth. That level of hiring, coupled with localized retirement waves, creates a structural shortage that technology can help mitigate.

Industry studies and trade groups also report near-term gaps: some analyses suggest a potential shortfall in certificated mechanics of tens of thousands by the late 2020s if training rates and hiring don’t accelerate. In the US alone, the current shortage is estimated at 10%, though this is expected to drop to slightly to around 6% at the end of the decade. However, this does not surpass demand, representing a gap of 4,200 certificated mechanics needed in 2035. These combined pressures create a strong business case for AI and robotic tools that stretch technician capacity and speed up turn times.

How AI and robotics actually help

AI and robotics reshape MRO from the inside out. Rather than relying on routine schedules and manual inspections, maintenance teams gain real-time visibility and automated support, as well as smarter decision pathways that reduce delays and strengthen safety performance.

Predictive maintenance (AI + sensors)

Traditional maintenance is calendar or utilization bases whereas AI enables condition-based and predictive models that spot failure patterns before they become events. Machine learning is able to ingests sensor telemetry, flight data and maintenance logs to forecast component life and advise targeted interventions. Studies and pilot projects demonstrate reductions in unscheduled removals and AOG (aircraft-on-ground) hours, and implementation reduces inventory costs and shrinks unscheduled downtime, both of which are critical drivers of MRO margins.

Drone and robotic inspections

Drones and crawler robots equipped with high-resolution cameras and LIDAR perform external inspections faster and more consistently than manual walk-rounds. For example, AI-enhanced image analysis automatically detects and flags paint corrosion, denting, delamination and fastener irregularities, producing annotated reports for technician review. These systems speed inspections and focus human attention where it’s needed most.

Robotic maintenance tasks

Robotic arms and automated torque/wrench systems are starting to take on repetitive, ergonomically demanding tasks such as precision fastener torquing, surface finishing, and non-destructive testing (NDT). Robots bring repeatability and can often operate in environments where human performance deteriorates over long shifts, improving quality while reducing fatigue-related mistakes.

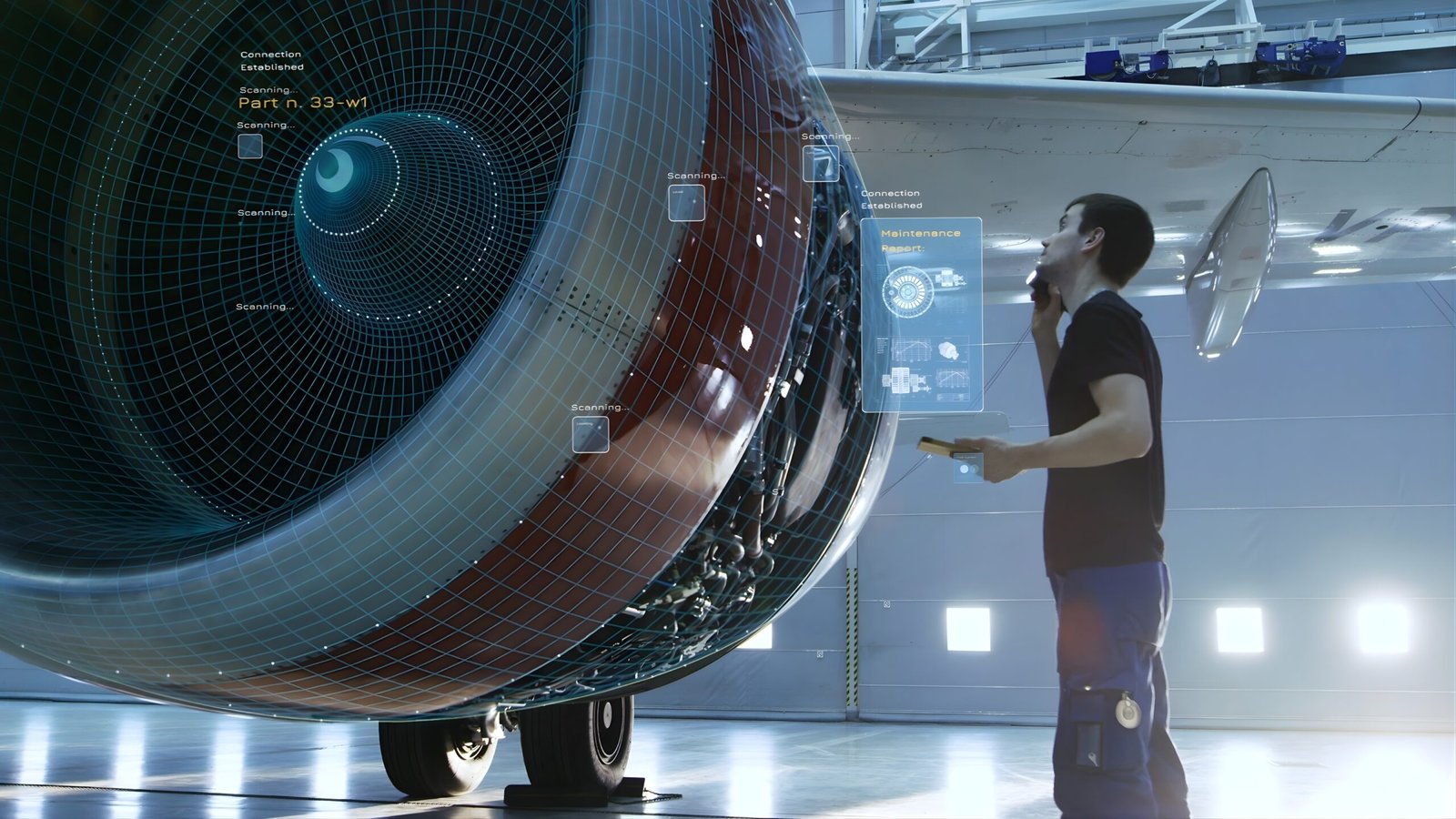

Digital twins and augmented reality (AR)

Digital twins is the name given to exact, data-driven replicas of aircraft systems. This allows engineers to run “what-if” scenarios, as well as test repairs virtually and validate outcomes before touching hardware. AR overlays provide step-by-step guidance to technicians, speeding up complex procedures and reducing error rates. These tools are particularly valuable for less experienced technicians, helping to close the skills gap fast.

Quantifiable benefits and early results

Operators and suppliers publishing pilot results report meaningful gains: predictive programs and AI analytics can reduce unscheduled maintenance events by 15–20% in some contexts. Digital-assist tools shorten task time and improve first-pass yield, and when multiplied across a fleet, these productivity gains convert directly into lower AOG costs and better aircraft availability.

Barriers: data, regulation and workforce change management

- Data quality and integration. AI needs clean, labeled, historical data. Many MROs still have siloed records or inconsistent logging practices; investing in data engineering is the first step to any AI payoff. A 2023 IATA study showed that 65% of MRO providers still use fragmented or paper-based maintenance records, and only about 20% have fully digitalized data systems required for AI models to operate effectively.

- Regulatory and certification requirements. Aviation is conservative by design and any tool that materially affects maintenance outcomes must satisfy regulators. That means careful validation, traceability and audit trails (which AI and digital tools can supply, but only with compliant processes).

- Workforce acceptance and upskilling. AI and robotics are not replacements for human expertise; they are force multipliers that remove repetitive tasks and free technicians to focus on complex diagnostics and higher-value problem-solving. According to Boeing’s 2024 long-term outlook, the global market will need 690,000 maintenance technicians by 2043; there is an increased demand for skilled personnel who can interpret data, manage automated systems and make critical judgements. With targeted training and thoughtful change management, today’s technicians can harness these technologies to advance their careers.

The human factor: technicians still matter

AI and robotics may accelerate inspections and shrink error margins, but the industry’s foundation still rests on human judgment and skilled technicians remain the ultimate arbiters of airworthiness. No algorithm can fully replace the intuition, contextual reasoning or safety-first mindset that experienced technicians bring.

In reality, the future of MRO depends on a productive partnership: human expertise amplified by machine accuracy. Technicians will interpret AI-generated alerts, validate sensor-driven recommendations and make the nuanced repair decisions that automated systems cannot yet understand.

“Automation can speed the work, but it’s people who keep aircraft safe.” Says AERVIVA’s CEO, Mindaugas Rainys. “The value of skilled technicians doesn’t diminish; it grows when supported by the right tools.”

Pragmatic adoption wins

AI and robotics still require investment and regulatory cooperation, but the upside is clear. With a projected multi-billion-dollar MRO market and long-term demand for technicians worldwide, operators that adopt AI and robotics thoughtfully will gain a competitive advantage: fewer disruptions, lower costs and higher safety margins.

As AERVIVA’s CEO Mindaugas Rainys puts it, “The future of MRO is human plus machine, and that partnership is ready to deliver measurable results.”